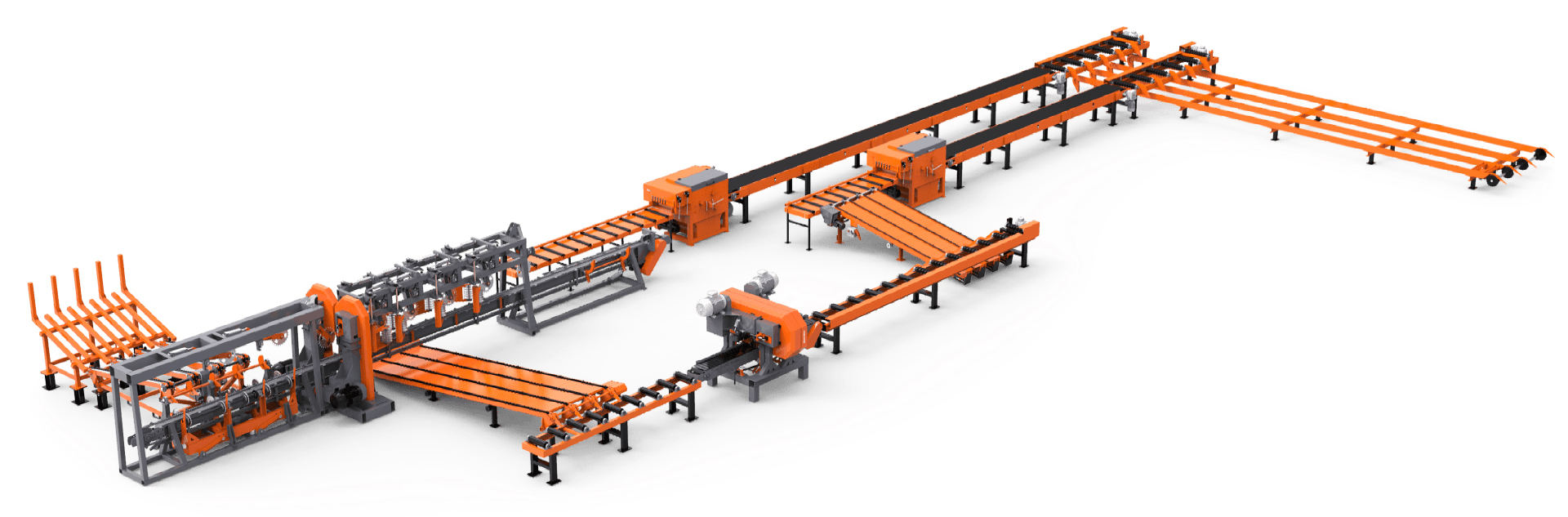

The TV2000 is an efficient and robust twin vertical saw for small to medium diameter logs up to 13ft (4m) in length. It is designed to break the log into a two-sided cant. The mechanized log loader allows for a single operator to rotate each log to the optimal position and then place it onto the moving sharp-chain. While moving through the blades, the log is held stable by multiple pressure feed rollers from the top, giving it unrivaled stability in the cut. The operator may select the desired cutting size and the machine will automatically adjust to that size in a fraction of a second, making it possible to saw unsorted logs, although Investing in log sorting capability increases log throughput and recovery. Once through the blades, multiple side pressure rollers engage the log on the outfeed, further reducing the chance of the log moving during the sawing process. Once clear of the blades, the side pressure rollers release, and the two slabs drop down, typically onto a slab cross-feed for further processing. The cant will continue straight, and be pneumatically kicked off and conveyed to the next step in the sawing process. The TV2000 is ideal for pallet mill and stud mill operations, where the product has relatively small cross-sectional dimensions.